|

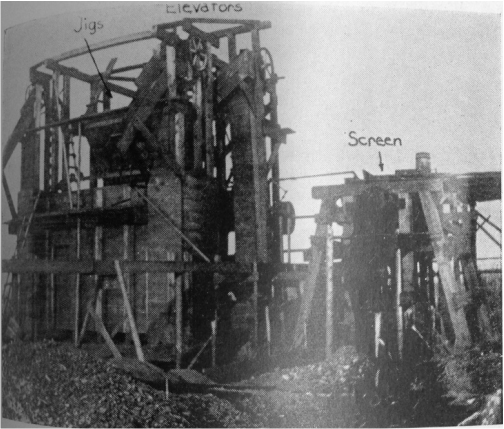

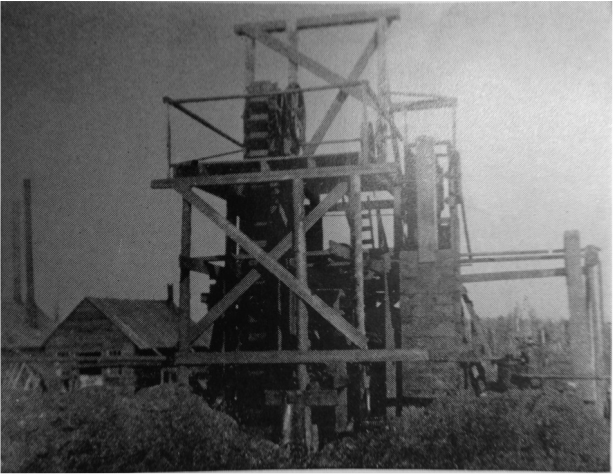

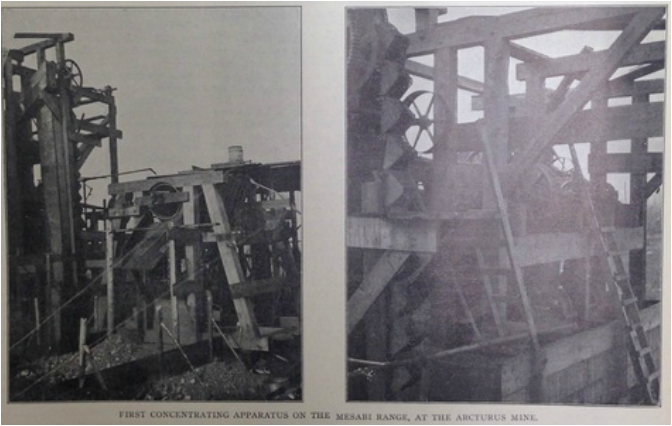

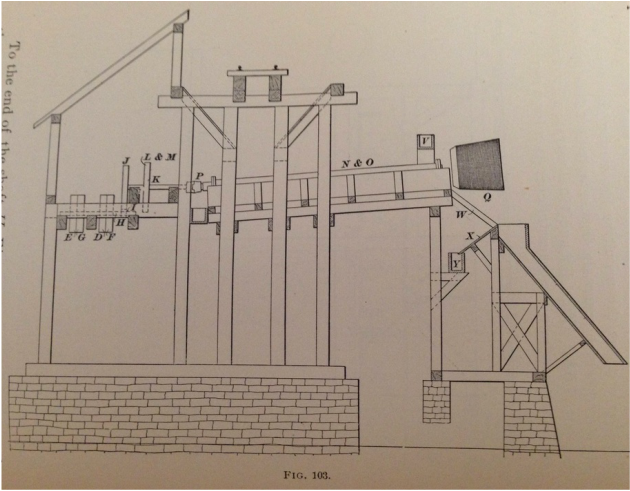

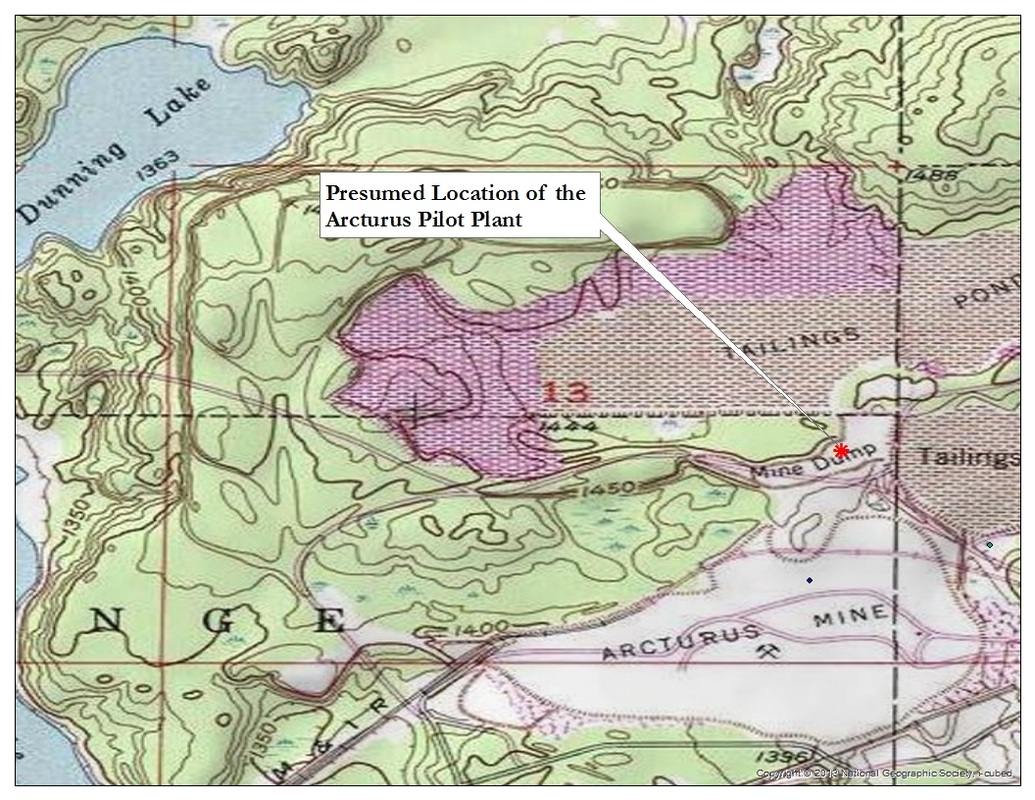

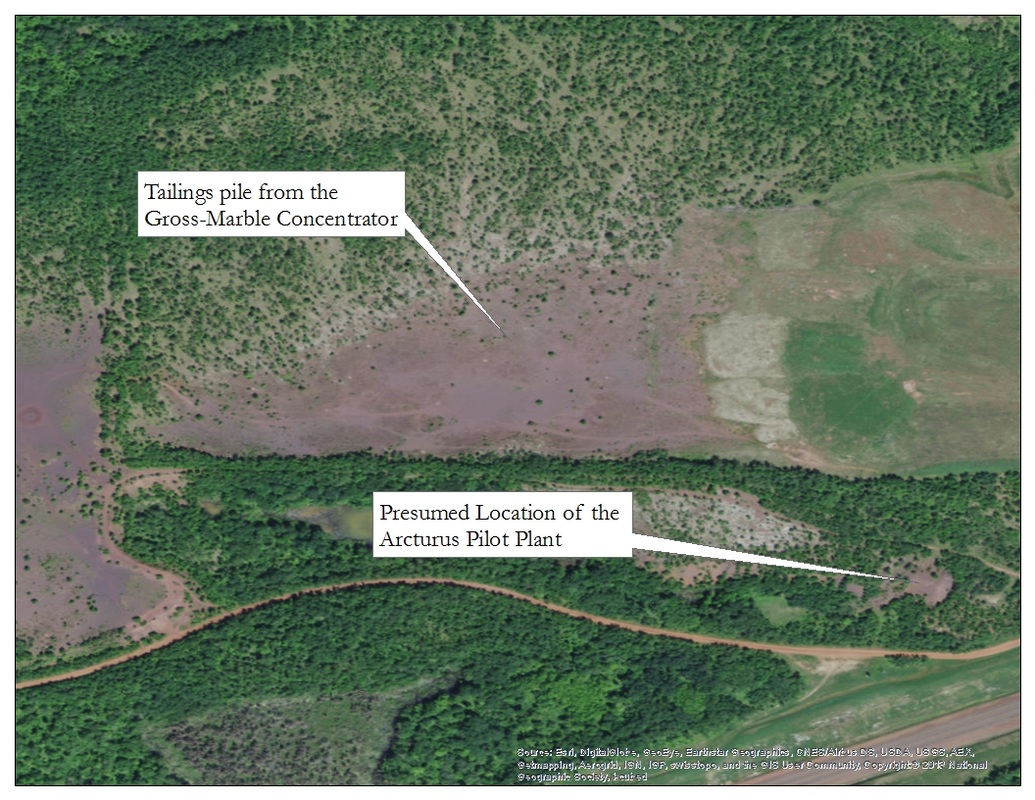

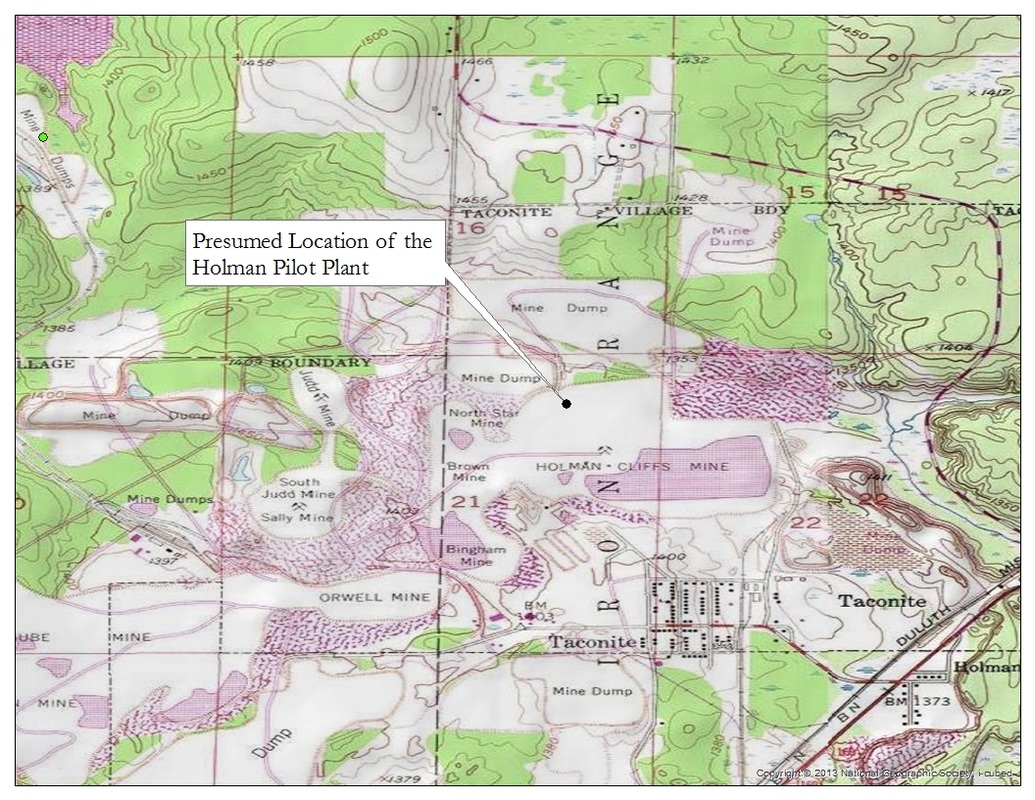

"But the experiment is being made on a most important scale by men of ample means who usually succeed in what they attempt." (Dwight E. Woodbridge, "Concentration of Mesabi Ores", in The Engineering and Mining Journal, Vol. 77, June 16, 1904, pp. 960-961.) Although the Trout Lake Concentrator was the first full scale, low-grade iron ore concentrator on the Mesabi Range, a handful of experimental (or pilot) plants proceeded it. Mining Companies were well aware of the potentially profitable low-grade iron ore deposits in the western Mesabi starting in the late 1890s, and by the turn of the twentieth century, The Oliver Iron Mining Co. (OIMC) took the first step in making this geologic probability an envirotechnical reality. The Acturus Mine, located roughly a mile northwest of Marble, MN, is where the story of Lake Superior iron ore concentration begins. Prior to 1900, the ore bodies in the Western Mesabi remained virtually untapped, due to a prevalence of high-grade shipping ore in the eastern part of the range, and the reported sandy constitution of the western ore body. Contemporary blast furnaces required iron ore to contain a high percentage of iron, around 60%, while the ore body in the western Mesabi averaged an iron content of less than 40%. When fed into a blast furnace, the high amounts of silica within the western Mesabi ores tended to clog the furnaces. Reportedly inspired by the success in concentrating low-grade iron ores elsewhere in the United States, The OIMC (along with the Snyder Mining Co., and the Canisteo Mining Co.) sent a railroad car of the western Mesabi sand low-grade ore south to be tested in a log-washing plant in Cedartown, Georgia. "These tests proved conclusively that that a merchantable ore could be produced by the washing process." Lawrence A. Roe, Iron Ore Beneficiation, Mineral Publishing Co., 1957, pp.7 Log washers are to low-grade iron processing as sluice boxes are to placer mines - indispensable technologies which relied upon practicality rather than extravagance. A log washer is employed to break off chunks of gangue (valueless material that is often found in the host rock containing ore) through a system of long poles with attached blades which rotate within a box filled with crushed ore and water. As the ore travels through the tilted log washer the blades agitate the ore so that the lighter gangue material separates from the ore. In the case of the Western Mesabi washable ores, the silica was seperated from the iron. Since the log washer box is tilted, the lighter silica material floats toward the downward end and is released through a discharge as tailings, while the heavier iron ore settles towards the bottom of the log washer and is transported towards the elevated end of the box through a screw system. For more on log washers click here The Arcturus Pilot Plant was constructed in 1902, and in 1903, a second experimental plant was erected at the Holman mine near Taconite, MN. "The following year, 1902, an experimental plant was built by J.W. Leech, for Chas. Purden, W.A. Barrows, Jr. and Eaton Brothers at the Arcturus mine...The next spring , 1903, a pilot plant was built at the Holman mine." (T.B. Counselman, "Beneficiating Minnesota Iron Ores", in Mining and Metallurgy, August 1941, pp. 405-406). "The results were satisfactory, and they subsequently installed a small screening and jigging plant on the (Arcturus) property. A screening plant was also installed by Chester A. Congdon and associates at the Holman mine near by. These plants demonstrated that a seperation could be made between the ore and the sand." Edmund Newton and Harlan H. Bradt, "Beneficiation of Lake Superior Iron Ores", in Mineral Resources of The United States 1915, pp. 305. By the end of October of 1903, The Arcturus Plant and the mine itself were idle. A shortlived success story that eventually gave way to the development of the Trout Lake Concentrator and many others soon followed. As both the Arcturus and Holman concentrators functioned as experimental plants their footprints are likely as ephemeral as the plants themselves. No signs of building foundations were evident in LIDAR imagery for the Arcturus plant, and the historic location of the Holman plant has been consumed by open pit mining, now a lake. Even though these plants left perhaps the smallest individual legacies, the experiments conducted within them produced favorable results which led to the development of an envirotechnical system that would transform the Western Mesabi into an industrial landscape in a matter of years.

1 Comment

James Doyle

1/26/2022 08:38:01

Well done its nice to be able to get back to the source. Jim Doyle

Reply

Leave a Reply. |

AuthorJohn Baeten holds a PhD in Industrial Heritage and Archaeology from Michigan Technological University. His research aims to contextualize the environmental legacies of industrialization as meaningful cultural heritage. Archives

May 2016

Categories

All

|

RSS Feed

RSS Feed